De-Mar & Associates, Inc

|

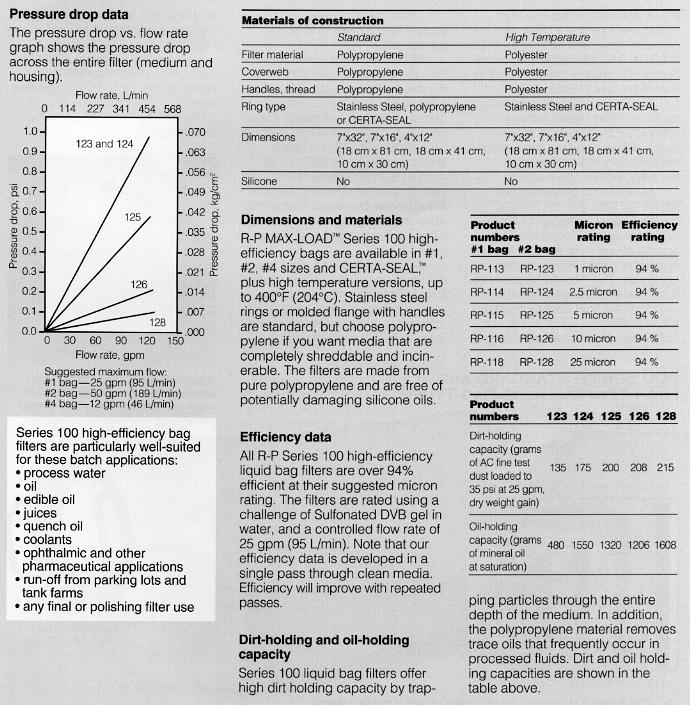

The MAX-LOAD™ Series 100 high-efficiency filter bag is made with one or more layers of melt-blown polypropelene microfibers between the inner and outer support layers. Furthermore, particle removal is highly repeatable and consistent throughout the bag, and from bag to bag. All Series 100 bags are over 94% efficient at their micron rating. By contrast, felt filter bags and string-wound or resin-bonded cartridges are often below 75% efficiency at their designated micron rating.

The #2 size Series 100 bags have a surface area of 4.4 square feet, compared to only 0.6 square feet for 10" string-wound, molded, or spray-spun cartridges. That's why these bags give you higher flows as well as excellent balance between higher efficiencies and low initial pressure drop.

By their nature, bags are quicker and cleaner to change out than cartridges so labor costs are lower and worker exposure is reduced.

The Series 100 bags also absorb unwanted trace oils that frequently occur in process fluids. In fact, they can hold from 10 to 20 times their own weight in oil. That's important when you're filtering compressor condensate water, bilge water, produced water or E-coat. If even more oil absorption is important to you, ask us about the Series 500 bags. They're up to 99% efficient at absorbing oil from process fluids.

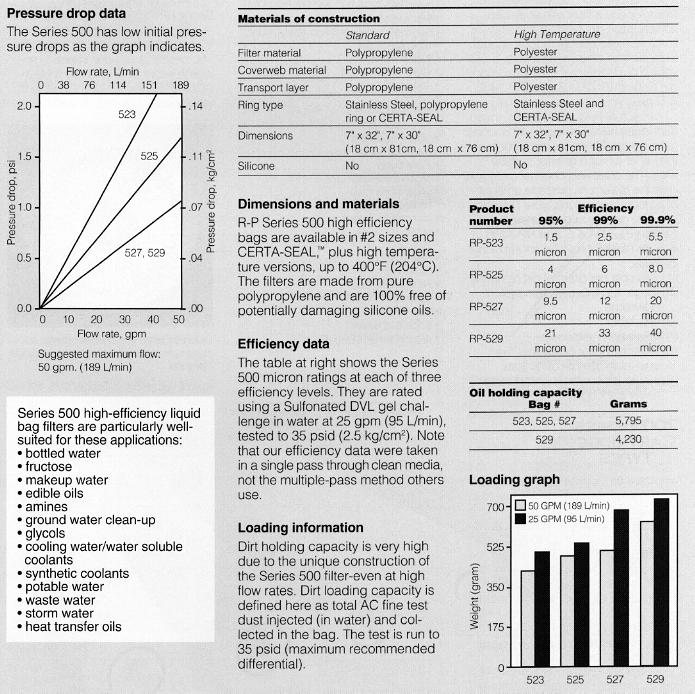

If your application requires high contaminant removal, minimal pressure drop, and filtering at Beta 1000 (99.9%) efficiency, the unique Series 500 graded density bag filter should be your choice.

The Series 500 high-efficiency liquid bag filter makes full use of every layer by providing graded levels of finer and finer filtration for exceptionally high dirt-loading capacity. Here's how it works.

As unfiltered process liquid enters the filter, the first layer of medium allows a portion of the fluid to pass through. Here the fluid is spread evenly over the next filtering layer where the filtering process continues. This filtering progression is carried out through several layers - until all the fluid passes through the final filtering layers, which are 100% melt blown filter material.

These bags provide up to 35 square feet of filter surface area.

Series 500 bags work harder than string-wound cartridges. For example, at 20 gpm a single 527 bag will collect 680 grams of dirt before it needs to be changed. At the same flow, it would take 29 30-inch string-wound cartridges to collect that much dirt. In that application, pressure drop across the 527 bag filter would be only 0.4 psid while pressure drop over the cartridges would be well over 3 psid.

The graded density filter technology is manufactured into a bag form to provide additional operational advantages, including faster and easier changeouts, compressibility for less expensive storage and disposal, and contaminant capture inside the bag for cleaner handling.

Series 500 bags are made of melt-blown polypropylene microfibers, felt and a choice of stainless steel ring, polypropylene ring, or CERTA-SEAL™ molded polypropylene flange.

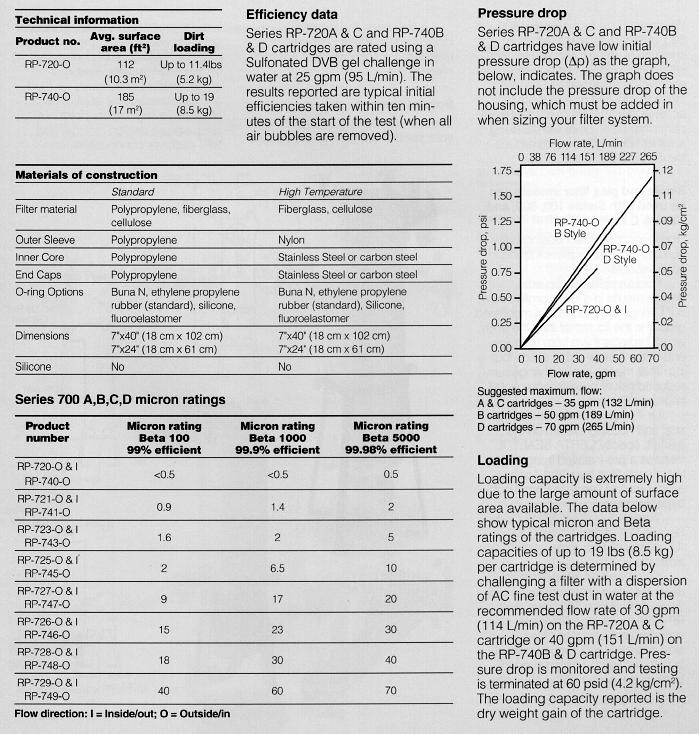

If your application has extended run times, needs a filter with an exceptionally large dirt-holding capacity, or involves materials hazardous enough to make filter changeout a very involved or dangerous chore, consider our Series RP-720A & C or RP-740B & D pleat and channel cartridge.

In actual field applications, these cartridges have held up to 19 pounds of contaminant simply because they offer a much greater surface area. The pleat and channel cartridge gets the maximum amount of filtering medium into your housing.

The greater surface area of the Series RP-720A & C and RP-740B & D cartridges provides six important benefits:

Another unique feature of the Series RP-720A & C style cartridges - they are available in two flow configurations - outside in, or inside out. The benefits is you don't have to re-plumb you housing to use a MAX-LOAD™ Series RP-720. Order to fit your needs. Just drop in and run.

| De-Mar & Associates, Inc | Kansas City Phone: 913-381-6810 | Kansas City Fax: 913-381-9332 |

| Parker & Foster Division | Wichita Phone: 316-794-2686 | Email: pfinc@birch.net |